- Applications

- Support

- Support Center

- Download

[ Manual E2 – How to Replace the Hot End – V1.0 ]

2 mm hex wrench

1.Power off the machine.

2.Release the buckle securing the ribbon cable by pinching the latch and opening the lever.

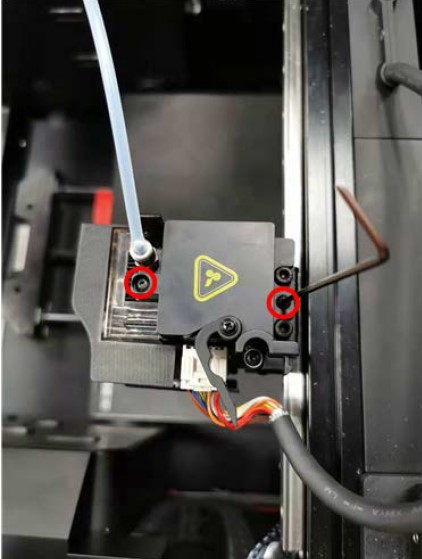

3.Use a 2 mm hex wrench, loosen and remove the two screws securing the extruder connection board cover to the print head.

4.Use a 2 mm hex wrench, remove the two screws securing the extruder connection board to the print head.

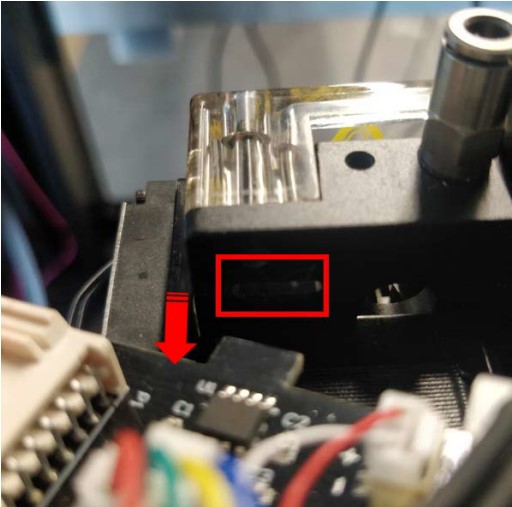

5.Gently pull out the extruder connection board in the direction of the arrow shown below. Be mindful of the small tab holding it in place.

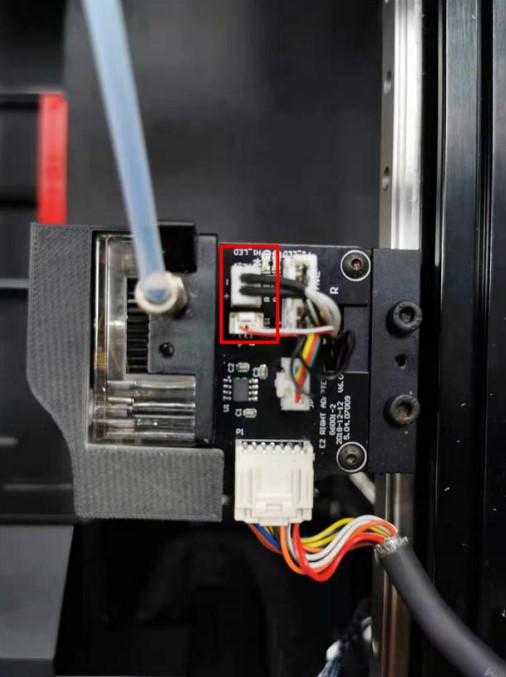

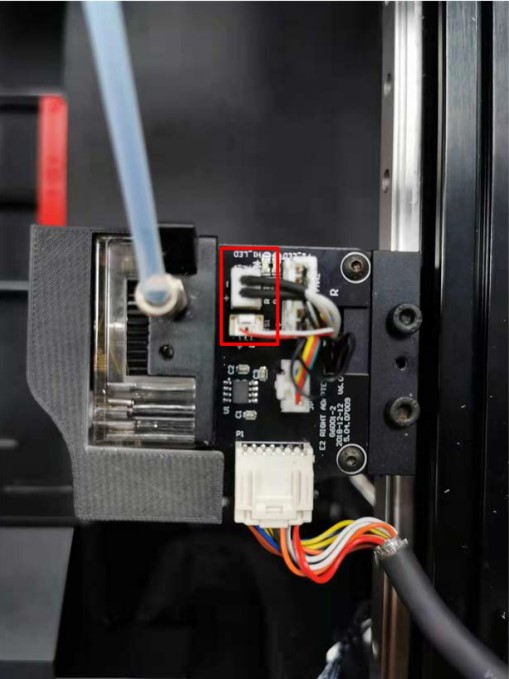

6.Unplug the two wires from the slots marked in red as shown in the picture below.

7.Use a 2 mm hex wrench to loosen the hot end set screw. At this step, the entire hot end assembly can be removed along with the heater rod and temperature sensor.

8.Remove the hot end.

9.Prepare a new hot end.

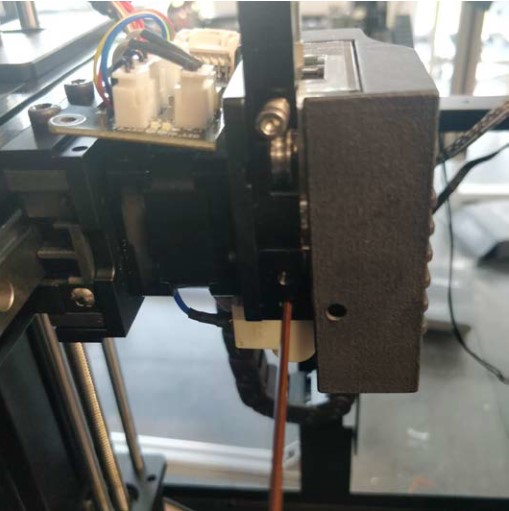

10.Insert the throat tube of the hot end back into the heat sink facing the back of the machine.

11.Once the throat tube is inserted fully into the heat sink, use a 2 mm hex wrench to tighten the screw securing the hot end.

12.Reinstall the extruder connection board by orienting the tab towards the feeding gear. Once it’s oriented properly, tuck the wires into the cable management slot.

13.Reconnect the heater rod cable to the terminal slot marked HE_0 or HE_1. Reconnect the temperature sensor cable into the terminal slot marked TS0 or TS1.

14.Retighten the two securing screws using a 2 mm hex wrench.

15.Reinstall the connection board cover with the buckle facing the ribbon cable socket.

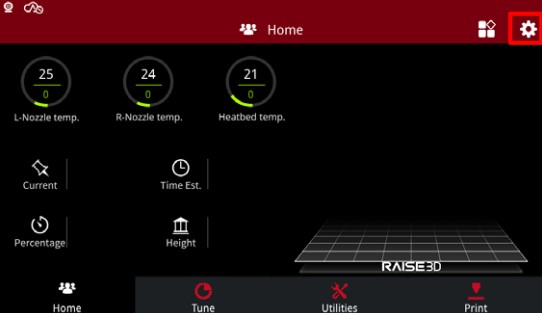

20.Press “Setting” icon.

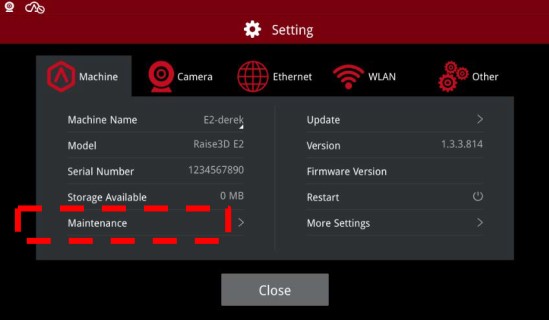

21.Select “Maintenance”.

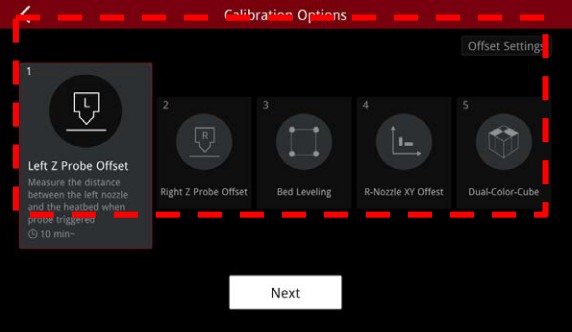

22.Select”Offset Calibration”.

23.Press ”Start”.

24.Wait until the printer runs the calibration and click ”Next”.

[ Manual E2 – How to Replace the Hot End – V1.0 ]

-END-