During the process of 3D printing with hard filaments such as PLA, ABS, PA, etc., sometimes you may find that missing print layer, thin print layer or random breakpoints and holes may appear on the printed model, which may be caused by the inconsistent extrusion. The loosening of lever arm is one of the causes of inconsistent extrusion. If you are experiencing inconsistent extrusion when using a Raise3D printer or using official or OFP (Open Filament Program)-recommended filaments, please do not be alarmed, you can follow the steps in the following tutorial to try to adjust the tightness of the lever arm.

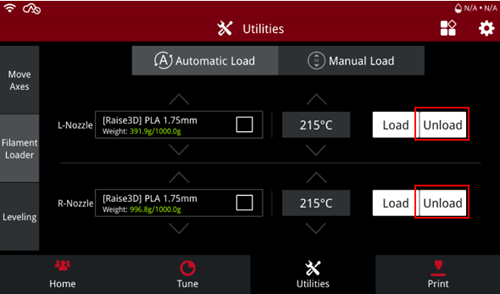

1.Select "Unload" in the "Utilities" tab to remove the filaments from the extruder that need to be adjusted.

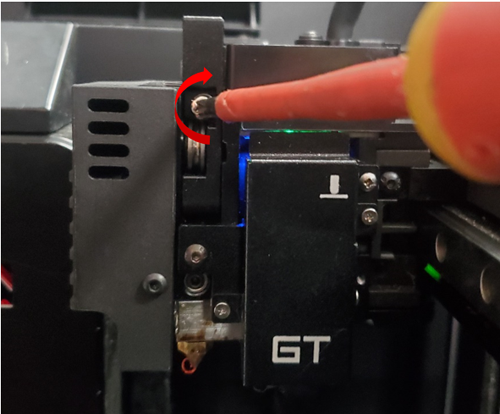

2.Use the Phillips screwdriver to fully tighten the lever arm screw clockwise.

Note: We will take the left print head as an example in this tutorial.

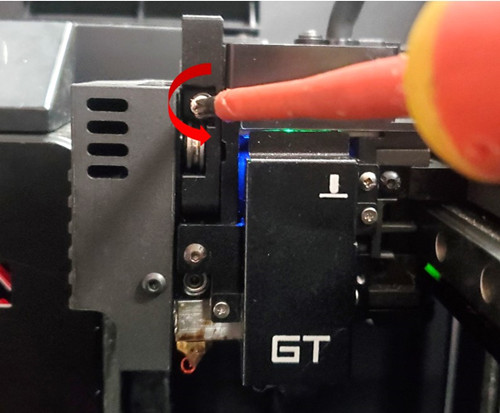

3.Then counterclockwise rotate the screw to loosen the lever arm slightly.

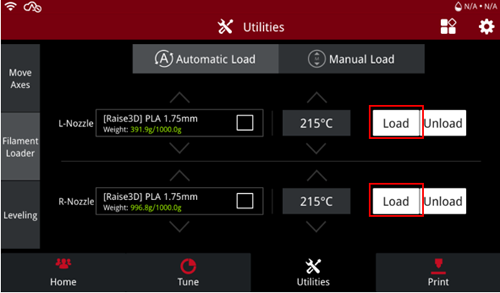

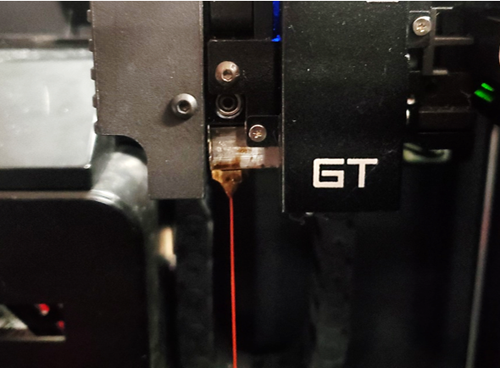

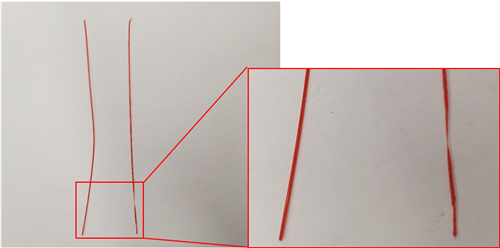

4.Select "Load" in the "Utilities" tab and load filament into the extruder. After the filaments have been extruded from the nozzle, observe if the filament is smoothly extruded.

5.The smoothly extruded filament should be of uniform thickness with no breaking points.

6.The lever arm has been adjusted to the proper tightness if the filament cannot be pulled outward during the feeding. If the extrusion is not smooth, or the filament can be pulled out during the feeding, you need to continue to adjust the screw tightness until the extrusion becomes smooth.

-END-