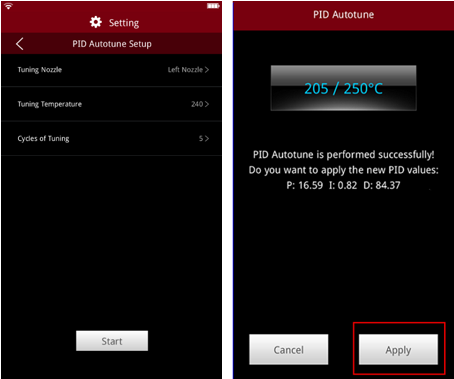

Click to enter the Auto Tuning interface, to select nozzle to be adjusted, set the required temperature and adjustment times, then click "Start". When the nozzle temperature is heated to the set temperature, select "Apply", the PID values will be applied to the screen.

Note: make sure the nozzle is cold when tuning the PID automatically. Otherwise, the adjusted PID may be inaccurate.

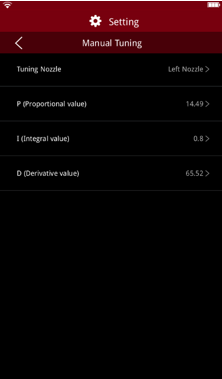

Click to enter the Manual Tuning interface to set the following parameters:

Choose the nozzle to tune and set PID.

P (Proportional value): the output of the controller is proportional to the input error signal.

I (Integral value): control the steady state error of the system.

D (Derivative value): speed up the reaction of the system.