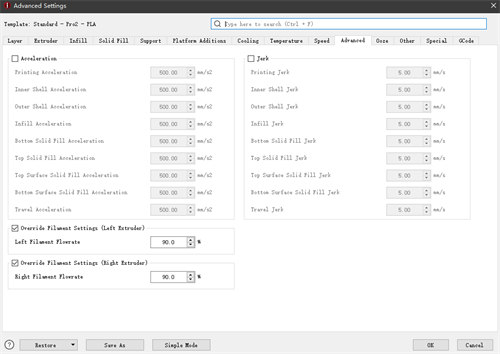

Enable Acceleration Control refers to enabling Acceleration Control function. The below settings will be activated such as Printing Acceleration.

(1) Acceleration

Acceleration is the rate of velocity changing of an object with respect to time.

Printing Acceleration refers to the printing acceleration speed for the non-specified area of the model.

Inner Shell Acceleration refers to the printing acceleration speed for the inner shell of the model.

Outer Shell Acceleration refers to the printing acceleration speed for the outer shell of the model.

Infill Acceleration refers to the printing acceleration speed for the infill structure of the model.

Bottom Solid Fill Acceleration refers to the printing acceleration speed for the bottom solid fill structure of the model.

Top Solid Fill Acceleration refers to the printing acceleration speed for the top solid fill structure of the model.

Bottom Surface Solid Fill Acceleration refers to the printing acceleration speed for the bottom surface solid fill structure of the model.

Top Surface Solid Fill Acceleration refers to the printing acceleration speed for the top surface solid fill structure of the model.

Travel Acceleration refers to the printing acceleration speed that the nozzle moves at from one place to another place without printing in X and Y directions.

Enable Jerk Control refers to enabling Jerk Control function. The below settings will be activated such as Printing Jerk.

(2) Jerk

Jerk is the maximum instantaneous velocity change.

Printing Jerk refers to the maximum instantaneous velocity change for printing model’s non-specified area.

Inner Shell Jerk refers to the maximum instantaneous velocity change for printing model’s inner shell.

Outer Shell Jerk refers to the maximum instantaneous velocity change for printing model’s outer shell.

Infill Jerk refers to the maximum instantaneous velocity change for printing model’s infill structure.

Bottom Solid Fill Jerk refers to the maximum instantaneous velocity change for printing model’s bottom solid fill structure.

Top Solid Fill Jerk refers to the maximum instantaneous velocity change for printing model’s top solid fill structure.

Bottom Surface Solid Fill Jerk refers to the maximum instantaneous velocity change for printing model’s bottom surface solid fill structure.

Top Surface Solid Fill Jerk refers to the maximum instantaneous velocity change for printing model’s top surface solid fill structure.

Travel Jerk refers to the maximum instantaneous velocity change when the nozzle moves at from one place to another place without printing in X and Y directions.

Jerk Settings support for Delta printers with this function enabled, ideaMaker will output M205 XYZ command to control the jerk value of Delta Printers.

Note:

1.This function is disabled by default.

2.This function only works for Delta Printers. For other printers, ideaMaker will still output M205 XY command to control the jerk value.

(3) Override Filament Settings

Enable this function, you can edit the filament flowrate. If you set the flowrate to be 95% in Filament Settings, but you enable this function and set it to be 90%, the Flowrate will change to 90%.

Note: When the “Override Filament Settings” option is enabled, the flowrate settings under this option take precedence over the flowrate in the “Material Settings screen”. So the final slice will use the flowrate under “Override Filament Settings”.

Left Filament Flowrate refers to the flow rate of left filament.

Right Filament Flowrate refers to the flow rate of right filament.

Figure 1: Advanced Tab.

-END-