(1) Repair

Merge Open Segments of Model Parts means merging the non-closed polygons in the model parts.

Merge Internal Overlapping Parts means merging the parts which are overlapped in interior of the model.

Print Non-Manifold Edges with this function enabled, ideaMaker will keep the model’s non-manifold edges during slicing, and it will be extruded as single extruding lines.

(2) Check Thin Wall (Single Extrusion Width) means that check if the width of the model parts is less than the defined thin wall width and extrude one single extrusion width to instead.

Minimal Extrusion Width Percentage refers to the minimal percentage of extrusion width.

Maximum Extrusion Width Percentage refers to the maximum percentage of extrusion width.

For Example, if the extrusion width is 0.4mm, set Minimal Extrusion Width Percentage to be 25% then the minimal thin wall will be 0.1mm. Set Maximum Extrusion Width Percentage to be 200%, then the maximum thin wall will be 0.8mm.

If item’s width is less than 0.1mm, it will print nothing as the width has less than minimal extrusion width. If item’s width is larger than 0.1mm, but less than 0.8mm, the system will extrude one single extrusion path instead and the width of the single path will be adapted to the size of space dynamically.

(3) Fill Gaps in Shells

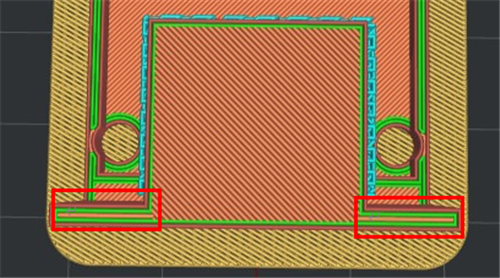

Fill Gaps in shells refers that with this function enabled, there will no gaps between shells as shown in Figure 1 and 2.

Allow Filling Gaps using Single Extrusion Filling refers that with this function enabled, the gap will be filled by single extrusion filling.

Minimal Single Extrusion Width Percentage refers to the minimal percentage of single extrusion width.

Maximum Single Extrusion Width Percentage refers to the maximum percentage of single extrusion width.

For example: if the extrusion width is 0.4mm, set the minimal singe extrusion width percentage to be 50%, which means the single extrusion width is 0.2mm. Set the maximum singe extrusion width percentage to be 200%, which means the maximum single extrusion width is 0.8mm. If the gap is less than 0.2mm, it will not be filled. If the gap is larger than 0.2mm and less than 0.8mm, it will be printed by single extrusion filling. And the width of the single extrusion filling will be adapted to the size of space dynamically.

Single Extrusion Filling Compensation with this function enabled, the small single extrusion filing structures will increase the flowrate so that the actual extrusion width will not fall below the specified value, rather than extruding nothing.

Note:

1. This function will change the E value of the GCode commands, but it does not affect the GCode preview.

2. Extruder will not extrude any filament if the extruding amount is too small.

Figure 1: "Fill Gaps in shells" enabled.

Figure 2: "Fill Gaps in shells" disabled.

(4) Overhang Shells Detection

Overhang Shells Detection - with this function enabled, the system will detect the structure of overhang shells automatically and modify the overhang shells’ printing speed and flowrate.

Overhang Shells Angle refers that if the Overhang Angles on the model are larger than the Overhang Shells Angle, shells on those parts of the model will be printed with settings set for Overhang Shells, including printing speed, flowrate and fan speed. The default Overhang Shells Angle will be 30 degrees.

Overhang Shells Flowrate refers to the flow rate at the overhang shells as a percentage of the filament flowrate.

Enable Overhang Shells Fan Speed allows the overhang shells’ cooling fan speed to be modified.

(5) Global Offset

Global Offset means that you can apply X/Y/Z offset to all coordinates in the GCodes.

You can separately set X-Offset, Y-Offset and Z-Offset.

(6) Pause at Height

Pause at Height means that the printer will automatically suspend a print job at the defined height. You can do several operations such as changing filament and resume the print then.

You can define the height by clicking the Add Pause Point button. And delete the defined height by selecting the value in right box and clicking the Remove Pause Point button.

Note: This height doesn’t include Raft. For Raise3D printers, ideaMaker outputs the M2000 command to tell the printer to pause at the specified position. For third-party printers, custom commands can be modified in Printer Settings > Advanced > Custom GCode > Pause at Height.

(7) Enable Bridging Detection

Enable Bridging Detection means that with this function enabled, the system will detect the bridge structure automatically.

Extrusion Width Percentage refers to the percentage of bridging extrusion width. For Example, if the extrusion width is 0.4 mm and you set this value to be 120% then the bridging structures extrusion width will be 0.48 mm.

Enable Bridging Fan Speed refers that with this function enabled the fan speed of bridging can be modified.

Enable Fixed Bridging Angle refers that with this function enabled the fill lines angle of bridging structures will be fixed as the value you set.

Minimal Allowed Bridging Area refers that if the bridging area is less than the value you set, ideaMaker will recognize that it is not bridging structure and instead of printing solid fill.

Bridging Flowrate refers to the flow rate of printing the bridging structure.

Maximum Supported Area Percentage refers that if the supported area is larger than the percentage of bridging area, then the bridging detection will be disabled at these regions. Set the option to 0 will disable bridging detection on all supported regions.

Apply Bridging Settings to Shells with this function enabled, the bridging shells’ speed and flowrate can be modified.

Bridging Shells Flowrate refers to the flow rate at the bridging shells as a percentage of filament flowrate.

Note: This option only takes effect when “Apply Bridging Setting to Shells” is enabled.

(8) Small Features

Note: Parts detected as “Small Features” can be printed at different speeds and fill densities to enhance print results. Common small features such as pins, which require slower speed to print, need a lot of time to cool the filament. Also, higher fill densities can increase the strength of the pins.

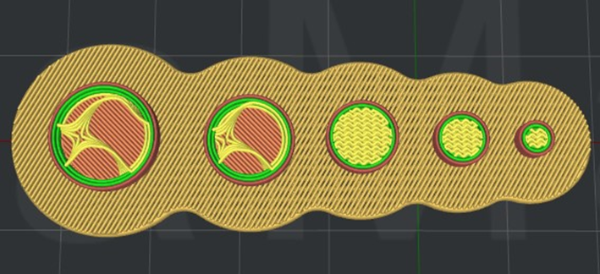

When the diameter of a selected area is lower than the set value, or when the diameter of holes on shells is lower than the set value, these sections will be printed out with the settings of Small Features, which requires a lower printing speed and the increased infill density.

Figure 3: The difference between Small Features and Non-Small Features printing.

Small Features Diameter refer to the regions where the detected small feature diameter is smaller than the defined value will be printed with Small Features settings.

Small Features Holes Diameter refer to the shells where holes of detected diameter are smaller than defined value will be printed with Small Features settings.

Small Features Speed Multiplier refer to the print speed percentage of small feature areas detected.

For example: if the Small Features Speed Multiplier is 50%, set the Infill Speed to 80mm/s, which means that the small features’ infill regions will be printed at the speed of 40mm/s.

Small Features Infill Density, with this function enabled, the infill density of detected small features area will be set as defined value.

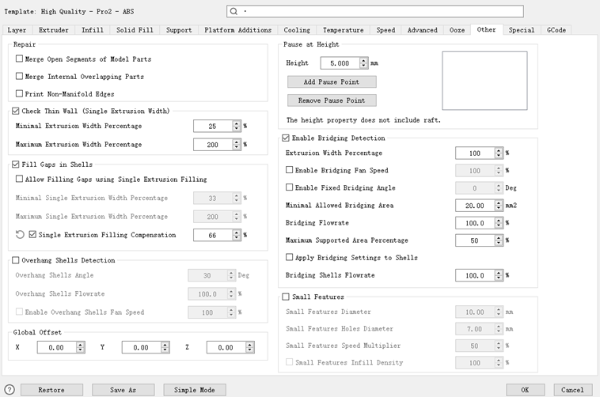

Figure 4: The Other Tab.