If you want to print a multiple-filament model, you need to arrange which extruder should print which part of the model, and then assemble the model in ideaMaker before slicing.

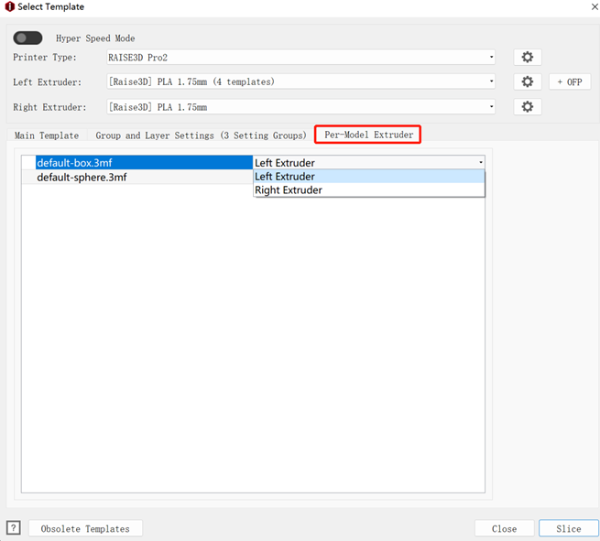

Option 1: Enter Select Template tab and click Per-Model Extruder for your model.

Figure 1: Select the extruder that will be used to print specific models

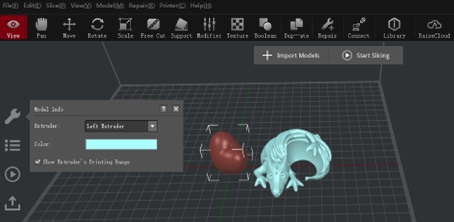

Option 2: Click View in menu bar and click model then choose extruder for your model.

Figure 2: Select the extruder that will be used to print specific models.

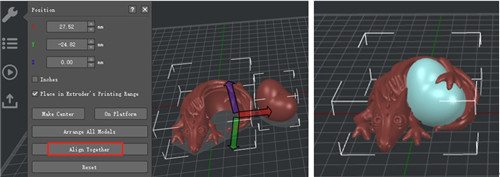

Figure 3: Try "Align Together" to align the models with "Move" enabled. If the models do not align properly, you may need to try to move the models manually.

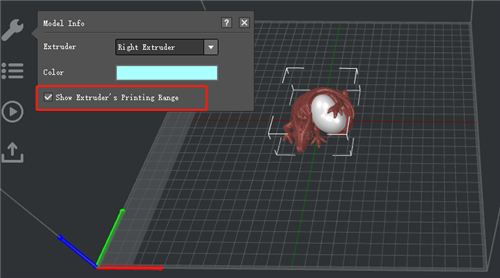

You can enable Show Extruder’s Printing Range to check whether your model is at correct range for each extruder when moving the models.

Figure 4: Check Right Extruder’s printing range.

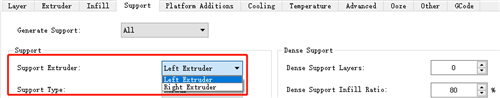

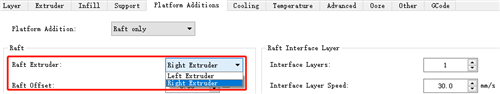

When slicing the model, if you want to use specific filament to print support and raft (such as soluble filament), you need to set the extruder for printing support and raft.

Figure 5: Select the extruder that will print support.

Figure 6: Select the extruder that will print the raft.

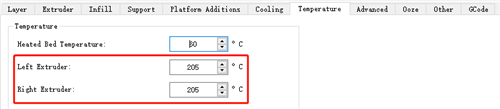

If you use different filament while printing in multiple-extruder-mode, you need to set the extruders’ temperature separately.

Figure 7: Confirm the temperature is suitable for your filament.

To print a better model that printed by multiple extruders, you also need to control multiple extruders’ ooze.

These settings as follows:

Force Retraction On Layer Change refers that the retraction will automatically be triggered the current layer print completes and the next layer starts.

Avoid Retraction Inside Model refers to disabling retraction when printing the inner structures of the model.

Extruder Switch Ooze Control refers to the retraction settings for extruder when one nozzle completes printing of one layer and the other nozzle starts printing.

Retraction Speed of Extruder-Switch refers to the speed of retraction when extruder switch.

Retraction Amount of Extruder-switch refers to the amount of filament retraction for an extruder change. 0 refers to no retraction at all.

Restart Speed of Extruder-switch refers to the extrusion speed after the retraction for an extruder change.

Extra Restart Amount of extruder-switch refers to the amount of additional filament compensation after the retraction for an extruder change.

Travel:

Avoid Traveling Through Holes refers to the printer will pass around the hole parts automatically to avoid leaving strings inside the holes.

Maximum Travel Path Length refers that the extruder will move through the hole directly, if the travel path length of move around the hole is longer than the maximum value.

Other:

Stop printing Wipe Wall and Wipe Tower if only one extrude is used in remaining task and the other extruder(s) will cooling down refers that, ideaMaker will detect how many extruders will be used in the remaining printing task, if it only uses one extruder, it will not print wipe wall and wipe tower any more, and it will stop heating the useless extruder.

To print a better model that printed by multiple extruders, you also need to control multiple extruders’ ooze.

See Chapter 5.1.3.11 for details of Wipe Wall.

-END-